-

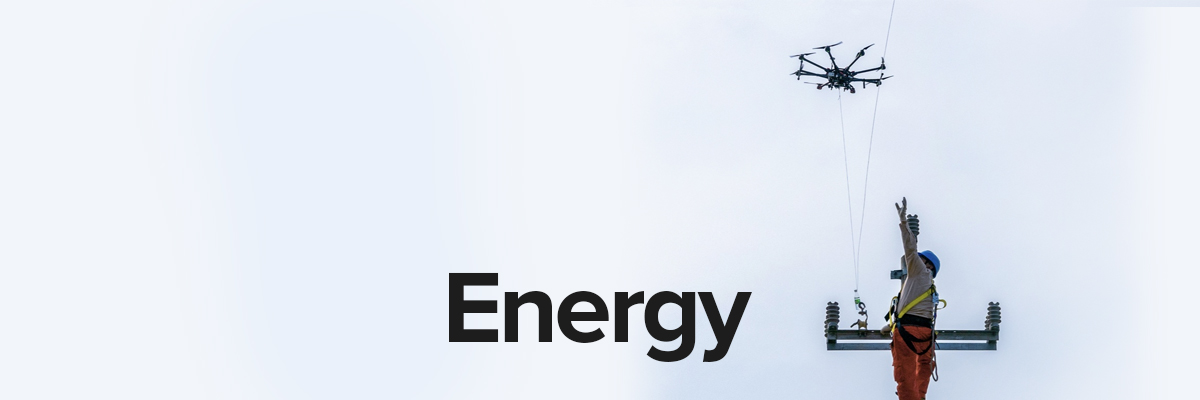

Manage Power Construction from Start to Finish

-

With advanced data capture capabilities across a variety of modelling formats and industry-standard outputs, enterprise drones can be used to assist electricity grid construction projects from start to finish.

-

By facilitating the planning and design stage through accurate modelling, construction progress monitoring with real-time data feedback and finally asset digitisation when projects are complete, enterprise drones provide project managers with all the data necessary for successful project execution.

-

How Can Drones Aid Electricity Construction Projects?

-

Compact yet powerful, enterprise drones can be used for efficient data collection at any stage of the construction process, from planning to completion.

-

Drones can also be used to assist during the construction process by providing up-to-date progress monitoring or physical assistance by lifting power lines to assist personnel during installation.

-

Additionally, drones can be used to complete site inspections after construction is completed including asset digitisation for future reference.

-

Electricity: Power Grid Management

-

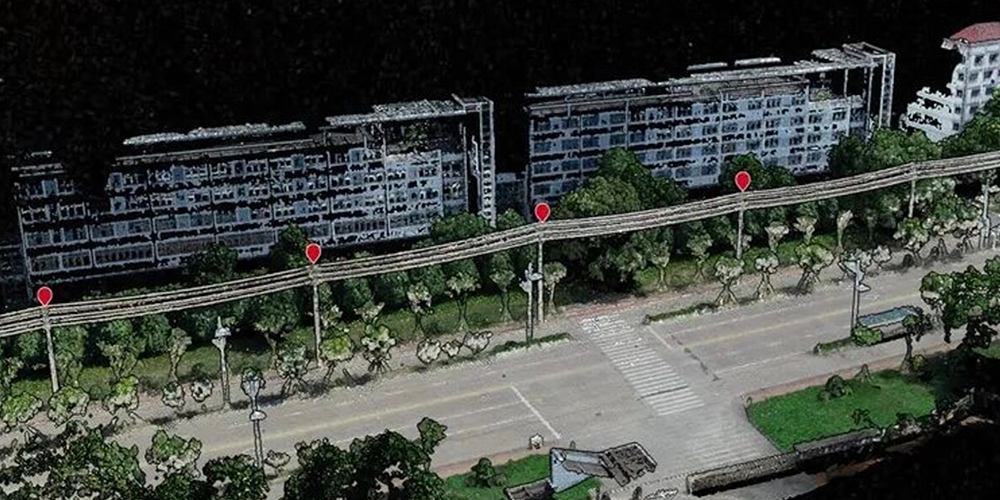

Power Your Planning

-

With the ability to navigate complex terrain and withstand adverse environments around electricity installations, enterprise drones can be utilised to conduct detailed inspections of power grids, boilers, wind turbines and more.

-

These inspections can be performed with flexibility based on the needs of a given project with options for thermal, nighttime and fault inspection available among others.

-

How Can Drones Aid Power Grid Management?

-

With flexible manoeuvrability and advanced sensor capabilities, enterprise drones can be used to perform inspections in places other equipment simply cannot.

-

Additionally, enterprise drones can be used to facilitate the management and maintenance of electric lines and facilities by providing temperature readings, measuring asset integrity and more.

-

Enterprise drones can be operated in complex terrains that other data-collection methods cannot, eliminating terrain-based bottlenecks for corridor mapping and planning projects. .

Oil & Gas: Production & Refinery Management

-

Maintain Efficiently and Effectively

-

Maintaining continual safe and efficient operation is of paramount importance in oil and gas refineries. Enterprise drones can be used to help ensure safe operations and rapid emergency response on work sites to improve personnel safety.

-

Enterprise drone solutions can be implemented to streamline processes and perform tasks including but not limited to facility management, leak detection and repair and asset digitisation.

-

How Can Drones Aid Production and Refinery Management?

-

Drones can be deployed to complete equipment inspections whilst operations are running, eliminating the need to shut down operations and lose value.

-

With the option for automated flights and inspections, drones can regularly be deployed to cover large areas for safety inspections and gas leak testing.

-

Furthermore, by receiving regular real-time information, site managers can make informed decisions that aid operational efficiency or coordinate rapid emergency responses when required.

Oil & Gas: Pipeline Integrity Management

-

Monitor and Manage with D1 Enterprise

-

With dynamic aerial capabilities, enterprise drone solutions can be used to monitor and maintain long oil and gas pipelines that cannot be monitored efficiently via other solutions. By gaining live aerial overview of pipeline conditions, potential risks including leaks can be identified and addressed efficiently.

-

How Can Drones Aid Pipeline Integrity Management?

-

Enterprise drones can aid pipeline integrity management in a variety of ways including general inspections, leak detection and repair, in addition to rapid emergency response.

-

With the constant risk of gas leaks present, drones can be used to efficiently scout long pipelines to detect leakage in order to speed up repair processes.

-

Additionally, drones can be deployed in emergency situations to map the scene of an accident, allowing emergency personnel to respond safely and effectively.

DJI Neo

DJI Neo DJI Neo Fly More Combo

DJI Neo Fly More Combo DJI Neo Motion Fly More Combo

DJI Neo Motion Fly More Combo DJI Care Refresh 1-Year Plan (DJI Neo)

DJI Care Refresh 1-Year Plan (DJI Neo) DJI Care Refresh 2-Year Plan (DJI Neo)

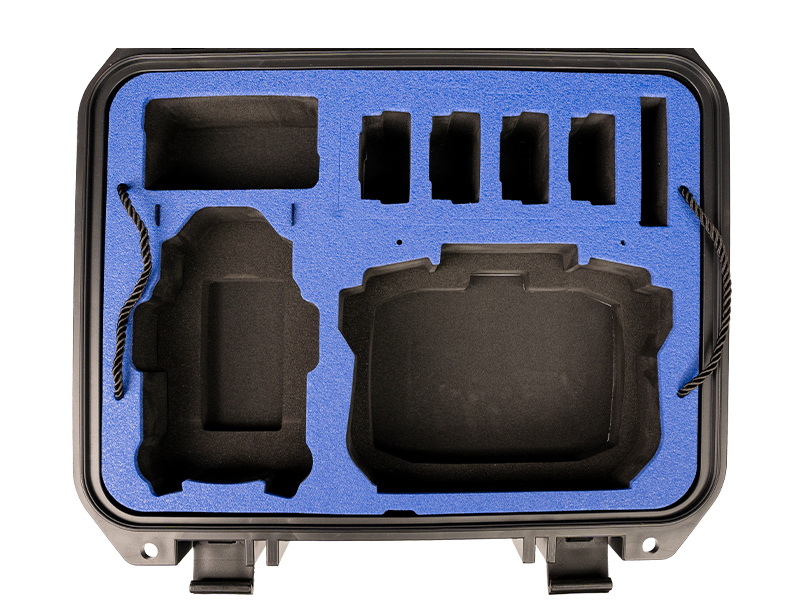

DJI Care Refresh 2-Year Plan (DJI Neo) D1 Labs Carry Case for DJI Neo

D1 Labs Carry Case for DJI Neo D1 Labs Carry Case for DJI Neo Fly More Combo

D1 Labs Carry Case for DJI Neo Fly More Combo DJI RC-N Series Control Sticks

DJI RC-N Series Control Sticks SunnyLife Bicycle Mount for DJI RC-N Series

SunnyLife Bicycle Mount for DJI RC-N Series D1 Labs Lanyard Kit for DJI RC-N Series

D1 Labs Lanyard Kit for DJI RC-N Series SunnyLife USB-C to Micro-USB Cable (30cm)

SunnyLife USB-C to Micro-USB Cable (30cm) D1 Labs Screen Protector for DJI RC Series

D1 Labs Screen Protector for DJI RC Series D1 Labs Lanyard Bracket for DJI RC Series

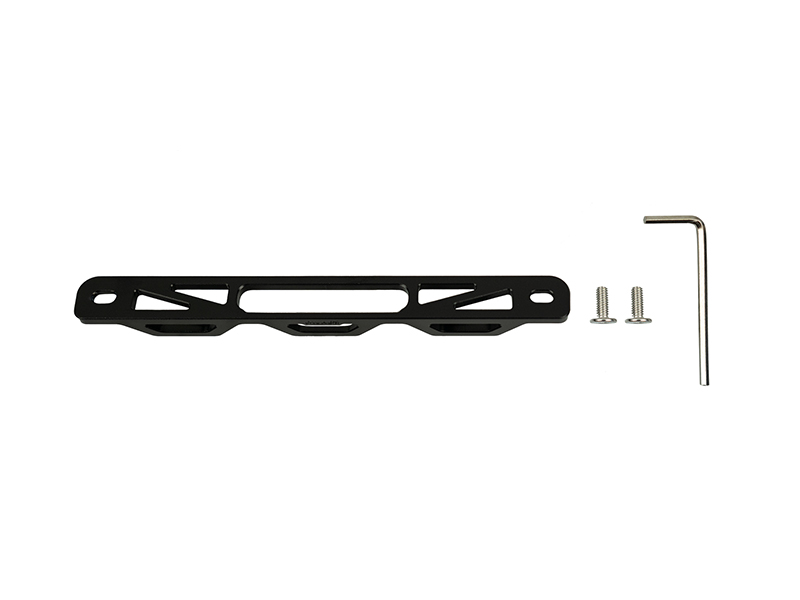

D1 Labs Lanyard Bracket for DJI RC Series D1 Labs Dual Hook Controller Lanyard

D1 Labs Dual Hook Controller Lanyard UGREEN Braided USB-C to USB-C Cable (1 Metre)

UGREEN Braided USB-C to USB-C Cable (1 Metre) Ulanzi Multifunctional Wrench | PT-18

Ulanzi Multifunctional Wrench | PT-18 D1 Labs Heli Landing Pad

D1 Labs Heli Landing Pad SanDisk Extreme Pro 128GB 200MB/s MicroSD Card

SanDisk Extreme Pro 128GB 200MB/s MicroSD Card SanDisk Extreme Pro 256GB 200MB/s MicroSD Card

SanDisk Extreme Pro 256GB 200MB/s MicroSD Card DJI Flip

DJI Flip DJI Flip w. DJI RC 2

DJI Flip w. DJI RC 2 DJI Flip Fly More Combo

DJI Flip Fly More Combo DJI Care Refresh 1-Year Plan (DJI Flip)

DJI Care Refresh 1-Year Plan (DJI Flip) DJI Care Refresh 2-Year Plan (DJI Flip)

DJI Care Refresh 2-Year Plan (DJI Flip) DJI RC 2

DJI RC 2 DJI RC-N3 Remote Controller

DJI RC-N3 Remote Controller DJI Mini 4 Pro Fly More Combo

DJI Mini 4 Pro Fly More Combo DJI Mini 4 Pro Fly More Combo Plus

DJI Mini 4 Pro Fly More Combo Plus DJI Mini 4 Pro

DJI Mini 4 Pro DJI Mini 4 Pro w. DJI RC 2

DJI Mini 4 Pro w. DJI RC 2 DJI Mini 3

DJI Mini 3 DJI Mini 3 Fly More Combo w. DJI RC

DJI Mini 3 Fly More Combo w. DJI RC DJI Mini 3 w. DJI RC

DJI Mini 3 w. DJI RC DJI Mini 3 Fly More Combo Plus

DJI Mini 3 Fly More Combo Plus DJI Mini 4K

DJI Mini 4K DJI Mini 4K Fly More Combo

DJI Mini 4K Fly More Combo DJI Mini 3 Pro w. DJI RC

DJI Mini 3 Pro w. DJI RC  DJI Mini 3 Pro

DJI Mini 3 Pro  DJI Mini 2 SE

DJI Mini 2 SE DJI Mini 2 SE Fly More Combo

DJI Mini 2 SE Fly More Combo DJI Mini SE

DJI Mini SE  DJI Mini SE Combo

DJI Mini SE Combo DJI Mini 2

DJI Mini 2 DJI Mini 2 Fly More Combo

DJI Mini 2 Fly More Combo  Mavic Mini

Mavic Mini Mavic Mini Fly More Combo

Mavic Mini Fly More Combo  DJI Air 3S

DJI Air 3S DJI Air 3S Fly More Combo

DJI Air 3S Fly More Combo DJI Air 3S Fly More Combo w. DJI RC 2

DJI Air 3S Fly More Combo w. DJI RC 2 DJI Air 3 Fly More Combo w. DJI RC 2

DJI Air 3 Fly More Combo w. DJI RC 2 DJI Air 3

DJI Air 3 DJI Air 3 Fly More Combo

DJI Air 3 Fly More Combo DJI Air 2S Fly More Combo

DJI Air 2S Fly More Combo Mavic Air 2 Fly More Combo

Mavic Air 2 Fly More Combo Mavic Air 2

Mavic Air 2 Mavic Air

Mavic Air  DJI Mavic 3 Pro w. DJI RC

DJI Mavic 3 Pro w. DJI RC DJI Mavic 3 Pro Fly More Combo w. DJI RC

DJI Mavic 3 Pro Fly More Combo w. DJI RC DJI Mavic 3 Pro Fly More Combo w. DJI RC Pro

DJI Mavic 3 Pro Fly More Combo w. DJI RC Pro DJI Mavic 3 Pro Cine Premium Combo

DJI Mavic 3 Pro Cine Premium Combo DJI Mavic 3 Classic w. DJI RC

DJI Mavic 3 Classic w. DJI RC  DJI Mavic 3 Classic

DJI Mavic 3 Classic DJI RC Pro Controller

DJI RC Pro Controller DJI Mavic 3

DJI Mavic 3  DJI Mavic 3 Fly More Combo

DJI Mavic 3 Fly More Combo  Mavic 2 Zoom

Mavic 2 Zoom Mavic 2 Pro

Mavic 2 Pro Mavic Pro Fly More Combo

Mavic Pro Fly More Combo DJI Avata 2 Fly More Combo

DJI Avata 2 Fly More Combo DJI Avata 2 Fly More Combo (Three Batteries)

DJI Avata 2 Fly More Combo (Three Batteries) DJI Avata Pro-View Combo w. DJI RC Motion 2

DJI Avata Pro-View Combo w. DJI RC Motion 2 DJI Avata Fly Smart Combo

DJI Avata Fly Smart Combo DJI Goggles 3

DJI Goggles 3 DJI Goggles N3

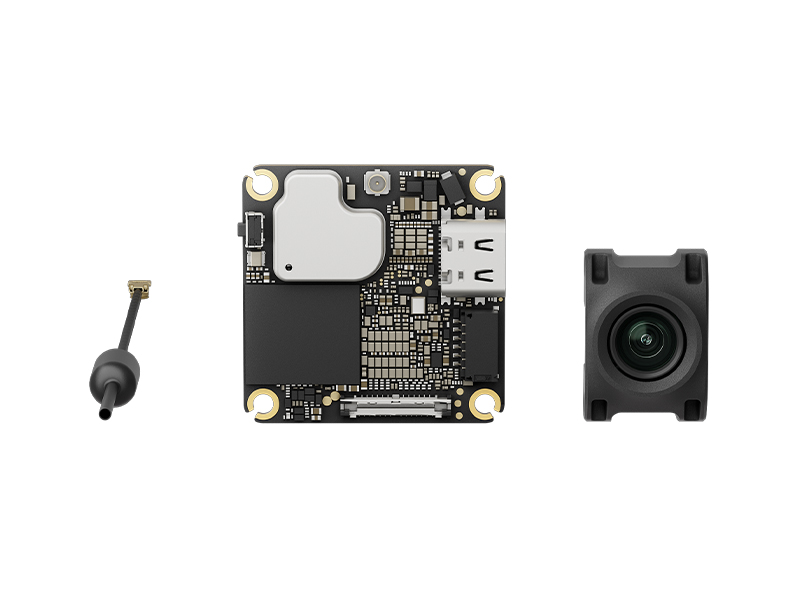

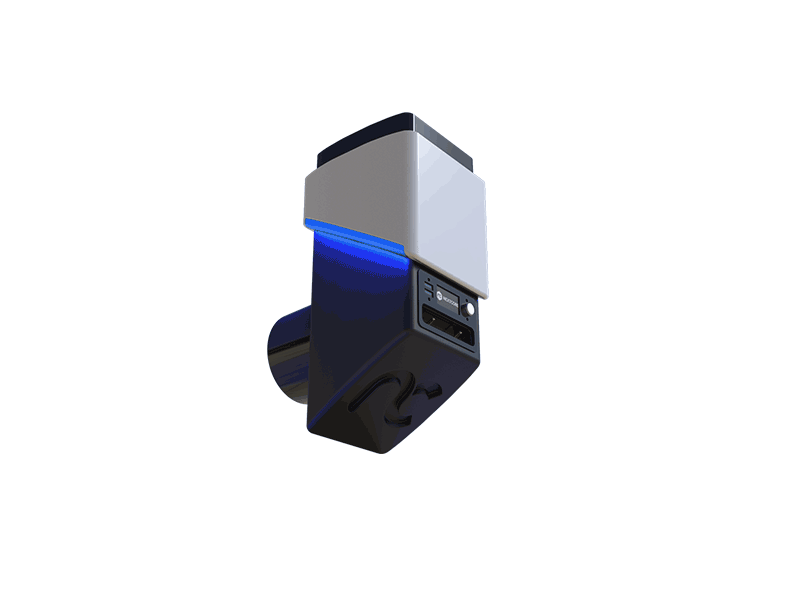

DJI Goggles N3 DJI O4 Air Unit

DJI O4 Air Unit DJI O4 Air Unit Pro

DJI O4 Air Unit Pro DJI O3 Air Unit

DJI O3 Air Unit DJI FPV Combo

DJI FPV Combo  Osmo Mobile 7

Osmo Mobile 7 Osmo Mobile 7P

Osmo Mobile 7P DJI Mic Mini Dual Microphone Combo

DJI Mic Mini Dual Microphone Combo DJI Mic Mini Single Microphone Kit

DJI Mic Mini Single Microphone Kit Osmo Action 5 Pro Standard Combo

Osmo Action 5 Pro Standard Combo Osmo Action 5 Pro Adventure Combo

Osmo Action 5 Pro Adventure Combo Osmo Pocket 3 Standard Combo

Osmo Pocket 3 Standard Combo Osmo Pocket 3 Creator Combo

Osmo Pocket 3 Creator Combo DJI Mic 2 Dual Microphone Combo

DJI Mic 2 Dual Microphone Combo DJI Mic 2 Single Microphone Kit

DJI Mic 2 Single Microphone Kit Osmo Action 4 Standard Combo

Osmo Action 4 Standard Combo Osmo Action 4 Adventure Combo

Osmo Action 4 Adventure Combo Osmo Mobile 6 (Slate Grey)

Osmo Mobile 6 (Slate Grey) Osmo Mobile 6 (Platinum Grey)

Osmo Mobile 6 (Platinum Grey) Osmo Mobile SE

Osmo Mobile SE DJI Mic Single Microphone Kit

DJI Mic Single Microphone Kit DJI Mic Dual Microphone Combo

DJI Mic Dual Microphone Combo Osmo Action 3 Standard Combo

Osmo Action 3 Standard Combo Osmo Action 3 Adventure Combo

Osmo Action 3 Adventure Combo  DJI Pocket 2

DJI Pocket 2 DJI Pocket 2 Creator Combo

DJI Pocket 2 Creator Combo DJI Action 2 Power Combo (128GB)

DJI Action 2 Power Combo (128GB) DJI Action 2 Dual Screen Combo

DJI Action 2 Dual Screen Combo DJI Action 2 Power Combo

DJI Action 2 Power Combo DJI Osmo Action

DJI Osmo Action  Osmo Pocket

Osmo Pocket DJI RS 4 Mini

DJI RS 4 Mini DJI RS 4 Mini Combo

DJI RS 4 Mini Combo DJI RS 4

DJI RS 4 DJI RS 4 Combo

DJI RS 4 Combo DJI RS 3 Mini

DJI RS 3 Mini DJI RS 3

DJI RS 3 DJI RS 3 Combo

DJI RS 3 Combo DJI RS 3 Pro

DJI RS 3 Pro DJI RS 2

DJI RS 2 DJI RS 2 Pro Combo

DJI RS 2 Pro Combo DJI RSC 2

DJI RSC 2 DJI RSC 2 Pro Combo

DJI RSC 2 Pro Combo Ronin-S

Ronin-S Ronin-SC

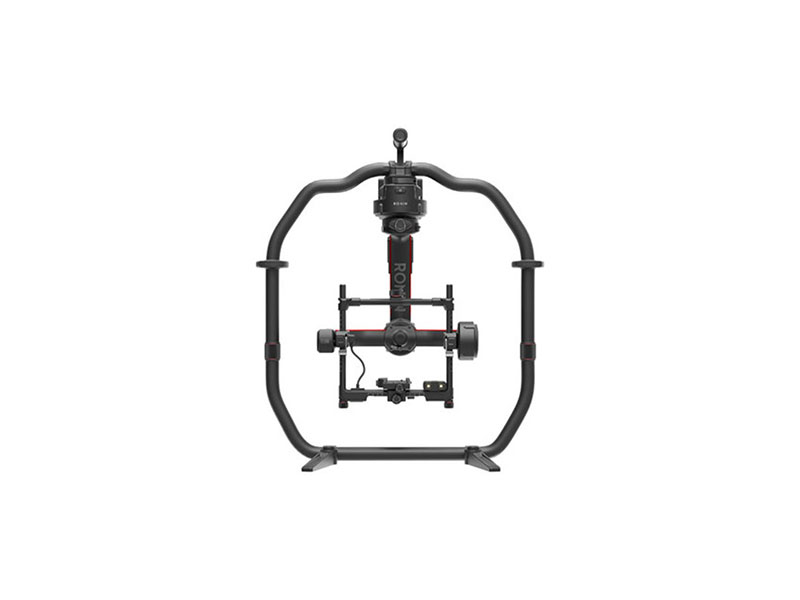

Ronin-SC Ronin 2 Professional Combo

Ronin 2 Professional Combo  Ronin 4D-6K

Ronin 4D-6K Ronin 4D-8K

Ronin 4D-8K Zenmuse X9-8K Gimbal Camera

Zenmuse X9-8K Gimbal Camera DJI Ronin 4D Flex

DJI Ronin 4D Flex DJI Inspire 3

DJI Inspire 3 DJI RC Plus for DJI Inspire 3

DJI RC Plus for DJI Inspire 3 DJI Focus Pro Creator Combo

DJI Focus Pro Creator Combo DJI Focus Pro All-In-One Combo

DJI Focus Pro All-In-One Combo DJI Transmission (High-Bright Monitor Combo)

DJI Transmission (High-Bright Monitor Combo) DJI Transmission (Standard Combo)

DJI Transmission (Standard Combo) DJI Video Transmitter

DJI Video Transmitter DJI Video Receiver

DJI Video Receiver DJI SDR Transmission Combo

DJI SDR Transmission Combo DJI SDR Transmission Receiver

DJI SDR Transmission Receiver DJI SDR Transmission Transmitter

DJI SDR Transmission Transmitter DJI DL 24mm F2.8 LS ASPH Lens

DJI DL 24mm F2.8 LS ASPH Lens DJI DL-S 16mm F2.8 ND ASPH Lens

DJI DL-S 16mm F2.8 ND ASPH Lens DJI DL 35mm F2.8 LS ASPH Lens

DJI DL 35mm F2.8 LS ASPH Lens DJI DL 50mm F2.8 LS ASPH Lens

DJI DL 50mm F2.8 LS ASPH Lens Inspire 2

Inspire 2 DJI Power 1000

DJI Power 1000 DJI Power Expansion Battery 2000

DJI Power Expansion Battery 2000 DJI Power 1.8kW Super Fast Charger 45A Car Charging Cable

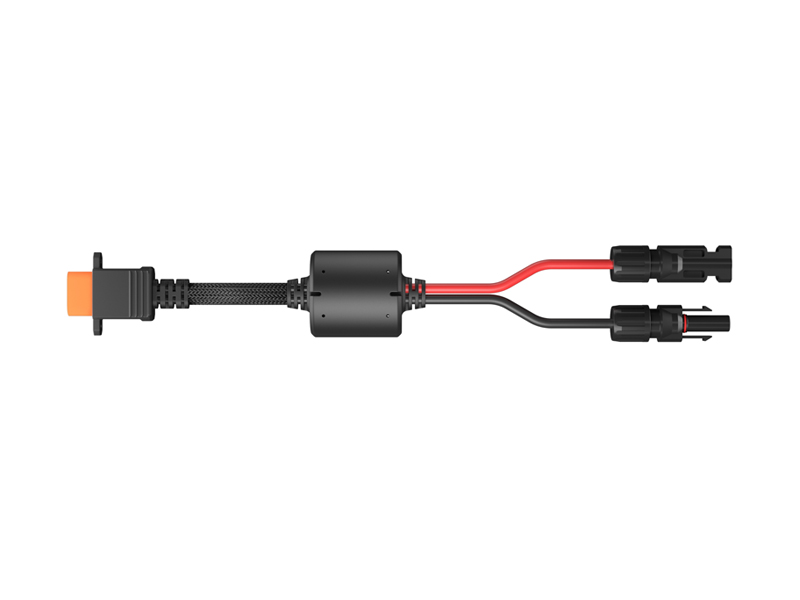

DJI Power 1.8kW Super Fast Charger 45A Car Charging Cable DJI Power 1.8kW Super Fast Charger XT90 to MC4 Adapter Cable

DJI Power 1.8kW Super Fast Charger XT90 to MC4 Adapter Cable DJI Power SDC to DJI Matrice 4 Fast Charge Cable

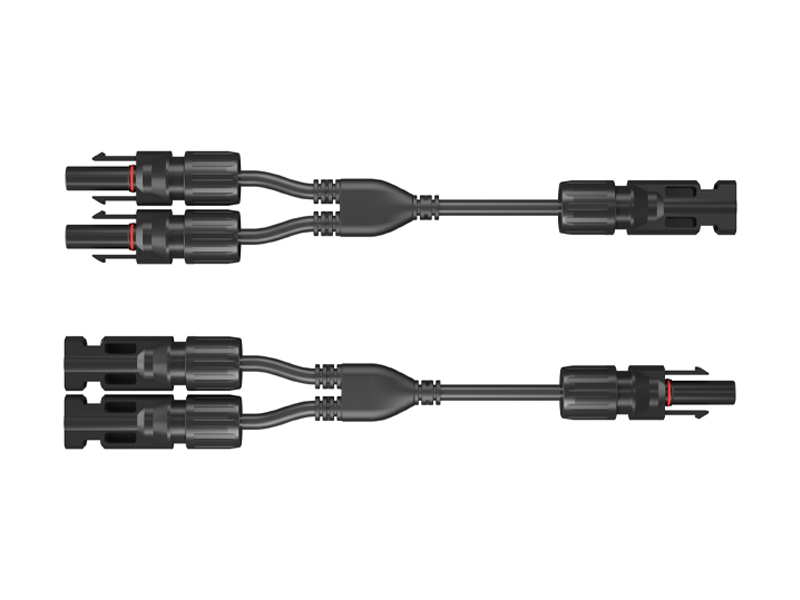

DJI Power SDC to DJI Matrice 4 Fast Charge Cable DJI Power Solar Panel MC4 Parallel Cable

DJI Power Solar Panel MC4 Parallel Cable Ex-Demo M30T Dock Bundle (Universal Edition)

Ex-Demo M30T Dock Bundle (Universal Edition) NextCore RN50 Drone LiDAR

NextCore RN50 Drone LiDAR Cendence-S Remote Controller For M200 V2 Series

Cendence-S Remote Controller For M200 V2 Series DJI FPV Lumicopter

DJI FPV Lumicopter D1 Labs Safety Case for DJI D-RTK 2

D1 Labs Safety Case for DJI D-RTK 2 Zenmuse H30

Zenmuse H30 Zenmuse H30T

Zenmuse H30T ParaZero SafeAir Parachute for Matrice 300 Series (ASTM Compliant)

ParaZero SafeAir Parachute for Matrice 300 Series (ASTM Compliant) DJI Dock 2

DJI Dock 2 DJI Matrice 4E

DJI Matrice 4E DJI Matrice 4T

DJI Matrice 4T DJI Matrice 4D

DJI Matrice 4D DJI Matrice 4TD

DJI Matrice 4TD Matrice 350 RTK

Matrice 350 RTK Zenmuse L2

Zenmuse L2 Zenmuse P1

Zenmuse P1 Phase One P3 Payload (iXM 120MP) with 80mm AF

Phase One P3 Payload (iXM 120MP) with 80mm AF DJI Mavic 3 Enterprise

DJI Mavic 3 Enterprise DJI Mavic 3 Thermal

DJI Mavic 3 Thermal DJI Mavic 3 Multispectral

DJI Mavic 3 Multispectral Matrice 30T

Matrice 30T DJI FlyCart 30

DJI FlyCart 30 DJI RC Plus for DJI FlyCart 30

DJI RC Plus for DJI FlyCart 30 ChengZhi GL300 Spotlight

ChengZhi GL300 Spotlight Matrice 300 RTK

Matrice 300 RTK  Deepthink S2 Pro Night Vision Payload

Deepthink S2 Pro Night Vision Payload Deepthink S2 Night Vision Payload for Matrice 300 Series

Deepthink S2 Night Vision Payload for Matrice 300 Series Mavic 2 Enterprise Advanced

Mavic 2 Enterprise Advanced Phantom 4 RTK (2 Battery)

Phantom 4 RTK (2 Battery) DJI D-RTK 2 High Precision GNSS Mobile Station

DJI D-RTK 2 High Precision GNSS Mobile Station AGRAS T50

AGRAS T50 AGRAS T25

AGRAS T25 AGRAS T40

AGRAS T40 DJI AGRAS T30 (Excluding Batteries)

DJI AGRAS T30 (Excluding Batteries) DJI AGRAS T10 (Excludes Batteries)

DJI AGRAS T10 (Excludes Batteries) DJI AGRAS T10 Ready To Fly (3pcs Battery)

DJI AGRAS T10 Ready To Fly (3pcs Battery) DJI Dock 3

DJI Dock 3 DJI Matrice 3D

DJI Matrice 3D DJI Matrice 3TD

DJI Matrice 3TD DJI Dock

DJI Dock  X2D 100C

X2D 100C Hasselblad X2D 100C Earth Explorer Limited Edition

Hasselblad X2D 100C Earth Explorer Limited Edition 907X & CFV 100C

907X & CFV 100C XCD 3,4/75P

XCD 3,4/75P XCD 2,5/25V

XCD 2,5/25V XCD 2,5/38V

XCD 2,5/38V XCD 2,5/55V

XCD 2,5/55V D1 Labs All-in-One Mount for Osmo Pocket 3

D1 Labs All-in-One Mount for Osmo Pocket 3 UGREEN 65W Nexode GaN II Charger

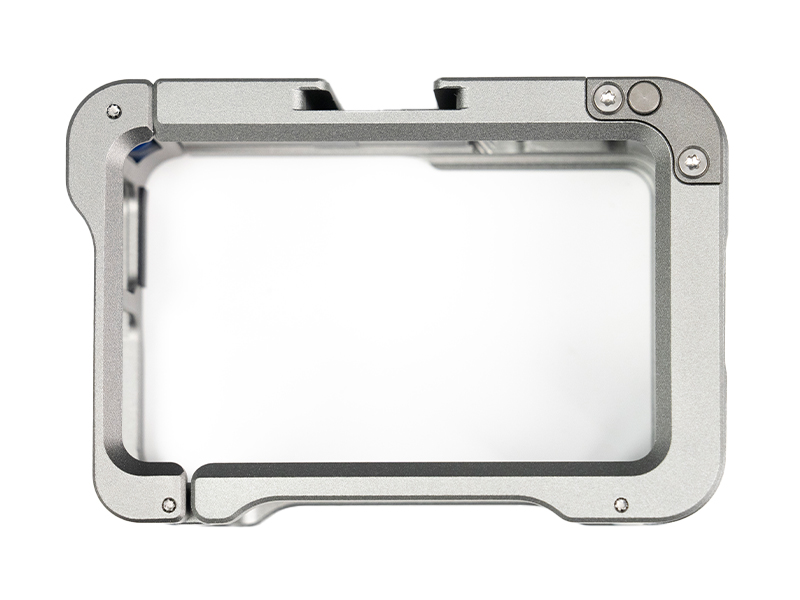

UGREEN 65W Nexode GaN II Charger D1 Labs Camera Cage for Osmo Action 3/4/5 Pro

D1 Labs Camera Cage for Osmo Action 3/4/5 Pro LiPO Battery Safe Bag (Medium)

LiPO Battery Safe Bag (Medium) DJI Care Refresh 1-Year Plan (DJI Mini 4 Pro)

DJI Care Refresh 1-Year Plan (DJI Mini 4 Pro) DJI Care Refresh 2-Year Plan (DJI Mini 4 Pro)

DJI Care Refresh 2-Year Plan (DJI Mini 4 Pro) D1 Labs Safety Case for DJI Mini 4 Pro

D1 Labs Safety Case for DJI Mini 4 Pro D1 Labs Carry Case for DJI Mini 4 Pro

D1 Labs Carry Case for DJI Mini 4 Pro DJI Care Refresh 1-Year Plan (Osmo Pocket 3)

DJI Care Refresh 1-Year Plan (Osmo Pocket 3) DJI Care Refresh 2-Year Plan (Osmo Pocket 3)

DJI Care Refresh 2-Year Plan (Osmo Pocket 3) D1 Labs Carry Case for Osmo Pocket 3

D1 Labs Carry Case for Osmo Pocket 3 DJI Care Refresh 1-Year Plan (Osmo Mobile 7P)

DJI Care Refresh 1-Year Plan (Osmo Mobile 7P) DJI Care Refresh 2-Year Plan (Osmo Mobile 7P)

DJI Care Refresh 2-Year Plan (Osmo Mobile 7P) DJI Mic Mini Transmitter (Arctic White)

DJI Mic Mini Transmitter (Arctic White) DJI Mic Mini Transmitter (Infinity Black)

DJI Mic Mini Transmitter (Infinity Black) DJI Care Refresh 1-Year Plan (Osmo Mobile 7)

DJI Care Refresh 1-Year Plan (Osmo Mobile 7) DJI Care Refresh 2-Year Plan (Osmo Mobile 7)

DJI Care Refresh 2-Year Plan (Osmo Mobile 7) BRDRC Wrist Strap for Osmo Series (Blue)

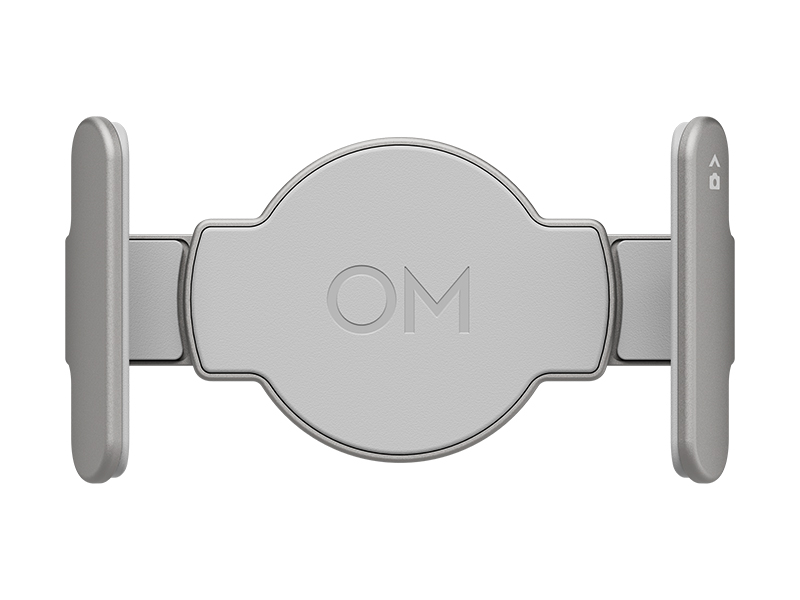

BRDRC Wrist Strap for Osmo Series (Blue) DJI OM Magnetic Phone Clamp 4

DJI OM Magnetic Phone Clamp 4 DJI Care Refresh 1-Year Plan (DJI RS 4 Mini)

DJI Care Refresh 1-Year Plan (DJI RS 4 Mini) DJI Care Refresh 2-Year Plan (DJI RS 4 Mini)

DJI Care Refresh 2-Year Plan (DJI RS 4 Mini) DJI RS Intelligent Tracking Module

DJI RS Intelligent Tracking Module DJI RS L-Shaped Multi Camera Control Cable (USB-C 30CM)

DJI RS L-Shaped Multi Camera Control Cable (USB-C 30CM) DJI Care Refresh 1-Year Plan (DJI Mavic 3 Pro)

DJI Care Refresh 1-Year Plan (DJI Mavic 3 Pro) DJI Care Refresh 2-Year Plan (DJI Mavic 3 Pro)

DJI Care Refresh 2-Year Plan (DJI Mavic 3 Pro) DJI Care Refresh 1-Year Plan (DJI Mavic 3 Pro Cine)

DJI Care Refresh 1-Year Plan (DJI Mavic 3 Pro Cine) DJI Care Refresh 2-Year Plan (DJI Mavic 3 Pro Cine)

DJI Care Refresh 2-Year Plan (DJI Mavic 3 Pro Cine) DJI Care Refresh 1-Year Plan (DJI Air 3S)

DJI Care Refresh 1-Year Plan (DJI Air 3S) DJI Care Refresh 2-Year Plan (DJI Air 3S)

DJI Care Refresh 2-Year Plan (DJI Air 3S) DJI Air 3S Intelligent Flight Battery

DJI Air 3S Intelligent Flight Battery DJI Care Refresh 1-Year Plan (DJI RS 4)

DJI Care Refresh 1-Year Plan (DJI RS 4) DJI Care Refresh 2-Year Plan (DJI RS 4)

DJI Care Refresh 2-Year Plan (DJI RS 4) Ulanzi Magic Arm with Cold Shoe Mount

Ulanzi Magic Arm with Cold Shoe Mount DJI Care Refresh 1-Year Plan (Osmo Action 5 Pro)

DJI Care Refresh 1-Year Plan (Osmo Action 5 Pro) DJI Care Refresh 2-Year Plan (Osmo Action 5 Pro)

DJI Care Refresh 2-Year Plan (Osmo Action 5 Pro) D1 Labs Screen & Lens Protector for Osmo Action 5 Pro

D1 Labs Screen & Lens Protector for Osmo Action 5 Pro Ulanzi Action Camera Cold Shoe Mount

Ulanzi Action Camera Cold Shoe Mount Freewell Standard Day Filters for Osmo Action 3/4/5 Pro (4 Pack)

Freewell Standard Day Filters for Osmo Action 3/4/5 Pro (4 Pack) DJI Care Refresh 1-Year Plan (Osmo Action 4)

DJI Care Refresh 1-Year Plan (Osmo Action 4) DJI Care Refresh 1-Year Plan (DJI RS 4 Pro)

DJI Care Refresh 1-Year Plan (DJI RS 4 Pro) DJI Care Refresh 2-Year Plan (DJI RS 4 Pro)

DJI Care Refresh 2-Year Plan (DJI RS 4 Pro) DJI Focus Pro LiDAR

DJI Focus Pro LiDAR DJI Mic 2 Transmitter (Pearl White)

DJI Mic 2 Transmitter (Pearl White) DJI Mic 2 Transmitter (Shadow Black)

DJI Mic 2 Transmitter (Shadow Black) DJI Mic 2 Camera Adapter

DJI Mic 2 Camera Adapter DJI Lavalier Mic

DJI Lavalier Mic Freewell CPL Filter for Osmo Action 3/4/5 Pro

Freewell CPL Filter for Osmo Action 3/4/5 Pro Freewell Mega Filter Pack for Osmo Action 3/4/5 Pro

Freewell Mega Filter Pack for Osmo Action 3/4/5 Pro DJI Mic Hot Shoe Adapter

DJI Mic Hot Shoe Adapter DJI Mic Series Carrying Pouch

DJI Mic Series Carrying Pouch DJI Mic Mobile Phone Adapter (Lightning)

DJI Mic Mobile Phone Adapter (Lightning) PolarPro CrystalSky Mount | Mavic/Spark

PolarPro CrystalSky Mount | Mavic/Spark  PolarPro Mavic 2 Pro Cinema Series 2-5 Stop VND Filter

PolarPro Mavic 2 Pro Cinema Series 2-5 Stop VND Filter PolarPro Vivid Collection Filters for Mavic Air 2 (3 Pack)

PolarPro Vivid Collection Filters for Mavic Air 2 (3 Pack) PolarPro 2 to 5 Stop VND Filter for Mavic Air 2

PolarPro 2 to 5 Stop VND Filter for Mavic Air 2 EM-D1 Drone Skin for DJI Mini 3 Pro

EM-D1 Drone Skin for DJI Mini 3 Pro UGREEN 35W Nexode GaN II Charger

UGREEN 35W Nexode GaN II Charger UGREEN USB-C to HDMI Adapter

UGREEN USB-C to HDMI Adapter UGREEN 6 in 1 USB-C Hub

UGREEN 6 in 1 USB-C Hub D1 VIP Device Activation & Setup

D1 VIP Device Activation & Setup Comprehensive Drone Insurance Services

Comprehensive Drone Insurance Services Remote Pilots License (RePL)

Remote Pilots License (RePL)  D1 Labs Landing Pad Pro (50CM)

D1 Labs Landing Pad Pro (50CM) D1 Labs Landing Pad Pro (65CM)

D1 Labs Landing Pad Pro (65CM) D1 Labs Landing Pad Pro (100CM)

D1 Labs Landing Pad Pro (100CM) PGYTECH OneMo FPV Backpack

PGYTECH OneMo FPV Backpack PGYTECH OneGo Backpack 18L (Obsidian Black)

PGYTECH OneGo Backpack 18L (Obsidian Black) PGYTECH OneMo 2 Backpack 25L | Space Black

PGYTECH OneMo 2 Backpack 25L | Space Black PGYTECH OneGo Air Backpack 25L | Obsidian Black

PGYTECH OneGo Air Backpack 25L | Obsidian Black DJI RC/RC 2 Control Sticks

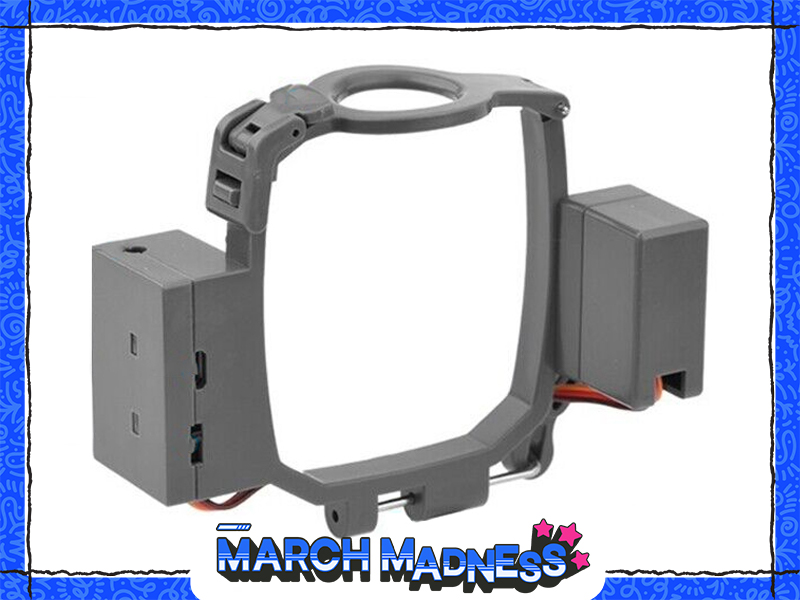

DJI RC/RC 2 Control Sticks Payload Release System for DJI Air 2S / Mavic Air 2

Payload Release System for DJI Air 2S / Mavic Air 2 Payload Release System for DJI Air 3 Series

Payload Release System for DJI Air 3 Series Payload Release System for DJI Mavic 2 Series

Payload Release System for DJI Mavic 2 Series Payload Release System for DJI Mavic 3 Series

Payload Release System for DJI Mavic 3 Series SunnyLife Protective Cover for DJI RC Pro

SunnyLife Protective Cover for DJI RC Pro SunnyLife Carrying Case for DJI RC Pro

SunnyLife Carrying Case for DJI RC Pro  D1 Labs Screen Protector for DJI RC Pro

D1 Labs Screen Protector for DJI RC Pro D1 Labs Lanyard Bracket for DJI RC Pro

D1 Labs Lanyard Bracket for DJI RC Pro D1 Labs Drone Safety Sign

D1 Labs Drone Safety Sign Retractable Drone Safety Cone 450mm

Retractable Drone Safety Cone 450mm LiPO Battery Safe Bag (Large)

LiPO Battery Safe Bag (Large)01.jpg) PGYTECH Memory Card Wallet

PGYTECH Memory Card Wallet D1 Labs 2 in 1 SD Card Reader

D1 Labs 2 in 1 SD Card Reader Freewell VND Filters for Osmo Pocket 3 (2 Pack)

Freewell VND Filters for Osmo Pocket 3 (2 Pack) Freewell ND4 Filter for DJI Avata 2

Freewell ND4 Filter for DJI Avata 2 Freewell Polariser Filter for DJI Avata 2

Freewell Polariser Filter for DJI Avata 2 Freewell Bright Day Filters for DJI Flip (6 Pack)

Freewell Bright Day Filters for DJI Flip (6 Pack) Freewell Sherpa Series CPL Filter

Freewell Sherpa Series CPL Filter Freewell Sherpa Series Glow Mist 1/4 Filter

Freewell Sherpa Series Glow Mist 1/4 Filter Freewell Sherpa Series 1-5 Stop VND Filter (Mist Edition)

Freewell Sherpa Series 1-5 Stop VND Filter (Mist Edition) Freewell Sherpa Series Long Range Macro Lens

Freewell Sherpa Series Long Range Macro Lens Freewell Galaxy Series Case for Samsung Galaxy S23 Ultra

Freewell Galaxy Series Case for Samsung Galaxy S23 Ultra Freewell Galaxy Series Snow Mist 1/4 Filter

Freewell Galaxy Series Snow Mist 1/4 Filter DJI RC Motion 3

DJI RC Motion 3 DJI FPV Remote Controller 3

DJI FPV Remote Controller 3 GameSir T1d Controller

GameSir T1d Controller PGYTECH CreateMate High-Speed Card Reader Case

PGYTECH CreateMate High-Speed Card Reader Case PGYTECH Camera Shoulder Strap

PGYTECH Camera Shoulder Strap PGYTECH Camera Wrist Strap

PGYTECH Camera Wrist Strap PGYTECH CFexpress CreateMate Card Reader Case (CFE-A/SD)

PGYTECH CFexpress CreateMate Card Reader Case (CFE-A/SD) Enterprise Shield For Mavic 2 Zoom

Enterprise Shield For Mavic 2 Zoom Enterprise Shield Mavic 2 Dual

Enterprise Shield Mavic 2 Dual Enterprise Shield Basic for Matrice 210 V2

Enterprise Shield Basic for Matrice 210 V2 Enterprise Shield Basic for Matrice 210 RTK V2

Enterprise Shield Basic for Matrice 210 RTK V2 PolarPro Vivid Collection Filters for DJI Air 2S (3 Pack)

PolarPro Vivid Collection Filters for DJI Air 2S (3 Pack) PGYTECH 2 to 5 Stop VND Filter for DJI Mavic 3

PGYTECH 2 to 5 Stop VND Filter for DJI Mavic 3 PGYTECH 6 to 9 Stop VND Filter for DJI Mavic 3

PGYTECH 6 to 9 Stop VND Filter for DJI Mavic 3 PolarPro VND Filters for DJI Air 2S (2 Pack)

PolarPro VND Filters for DJI Air 2S (2 Pack) Ex-Demo DJI Neo

Ex-Demo DJI Neo Ex-Demo DJI Mavic 3 Pro w. DJI RC

Ex-Demo DJI Mavic 3 Pro w. DJI RC Ex-Demo DJI Mavic 3 Pro Combo w. DJI RC

Ex-Demo DJI Mavic 3 Pro Combo w. DJI RC Ex-Demo DJI Avata Pro-View Combo w. DJI RC Motion 2

Ex-Demo DJI Avata Pro-View Combo w. DJI RC Motion 2 Ex-Demo DJI Mic 2 Transmitter (Shadow Black)

Ex-Demo DJI Mic 2 Transmitter (Shadow Black) Ex-Demo DJI Mic 2 Dual Microphone Combo

Ex-Demo DJI Mic 2 Dual Microphone Combo Ex-Demo DJI RS 4 Combo

Ex-Demo DJI RS 4 Combo Ex-Demo Osmo Action 4 Standard Combo

Ex-Demo Osmo Action 4 Standard Combo Ex-Demo DJI TB51 Intelligent Battery

Ex-Demo DJI TB51 Intelligent Battery Ex-Demo Matrice 200 TB55 Intelligent Flight Battery

Ex-Demo Matrice 200 TB55 Intelligent Flight Battery Ex-Demo DJI Mini 2 Series Two-Way Charging Hub

Ex-Demo DJI Mini 2 Series Two-Way Charging Hub Ex-Demo DJI Air 2 Series Battery Charging Hub

Ex-Demo DJI Air 2 Series Battery Charging Hub Ex-Demo Zenmuse H20N

Ex-Demo Zenmuse H20N Ex-Demo Mavic 2 Enterprise Dual w. DJI Smart Controller

Ex-Demo Mavic 2 Enterprise Dual w. DJI Smart Controller Ex-Demo DJI Mavic 3 Enterprise

Ex-Demo DJI Mavic 3 Enterprise Ex-Demo DJI Mavic 3 Thermal

Ex-Demo DJI Mavic 3 Thermal